VI. Stability and Decline 1965-1982

A. Phil Wood, Plant Manager

Phillip C. Wood came to Acklin in 1942 from The University of Toledo's engineering school. During the war production effort Wood had worked as a metallurgist on the shell line. From there he moved to the estimating department, then standards, before entering the engineering department. During the early 1950s, Wood served as a production engineer before being promoted to Chief Engineer. By 1955, Wood had moved up to the position of Plant Manager, overseeing the efficient operation of the plant's production effort on a day-to-day basis.

In 1965, the year Wood was appointed to the Plant Manager position, Acklin Stamping hit a brief period of slowdown. During the early months of the year, a steel strike seemed to loom on the horizon; as a precaution, Acklin overstocked its supply of steel and when the strike didn't occur the company was left with a large amount of expensive steel. This, combined with a cool summer and a slowing demand for refrigerators, caused layoffs in the late summer and early fall of 1965.

Production began to climb slowly through 1966 and 1967. A strike at Tecumseh Products in 1968 slowed work down for a few months but by 1969, production was again at full tilt. The first large surge in production from the late 1940s through the late 1950s was connected to the rapid expansion of the refrigerator market. However, by the mid 1960s, this market had begun to shrink. The late 1960s saw a period of growth in the air conditioning market as more and more Americans purchased units for their cars, homes, and businesses. As a result, 1968 and 1969 were extremely busy years, with Acklin producing between 30,000 and 40,000 compressor casings daily for sales of 19 million dollars each year.

B. The 1970s - Problematic Prospects

Acklin's prosperity continued into the early 1970s. Tecumseh's investment from 1966-1970 of nearly 1 1/2 million dollars into new equipment and buildings for Acklin kept the company on the cutting edge of technology. Demand for air conditioner compressors remained high and business was good. In December of 1970, Acklin stamped the 100 millionth compressor housing made at the company, nearly 75 million of which were produced following Tecumseh's purchase of Acklin.

Acklin Stamping Plant Aerial Photo, 1970s.

Acklin Stamping Plant Aerial Photo, 1970s.

But things would never again be so good. In 1971, the first signs of a nationwide recession began to appear. Foreign imports, which sold far more cheaply than domestic goods, began to cut into the demand. Increased automation began to eat away at the number of workers required to produce the same amount of output.

The introduction of safety laws and the formation of OSHA, the Occupational Safety and Health Administration in 1970, created yet another economic hurdle Acklin had to leap. In order to bring all of their equipment into compliance, large capital investments had to be made, money that otherwise would go to new equipment. Acklin's own safety program, which was begun by the union and the management in the early 1950s, as well as increasingly automated machinery, had already created a reduction in accidents.

In 1972, Tecumseh spent $350,000 on capital improvements, including safety modifications; electric lift trucks; and new housing washing machines.

By the mid 1970s the energy crisis had begun to affect Acklin. Increasing fuel prices drove up the costs of operation and furthered the demand for more efficient and automated presses. These changes caused Acklin to form an Energy Conservation Committee in 1973. The committee was made up of both management and union leaders and was in charge of finding solutions to the problems presented by the energy shortage. Their recommendations included cutting back use of natural gas and instead using heating oil, and better utilizing heat sources within the plant -- during the cold winter months, they placed fans near the machines to distribute that heat, rather than running the furnace.

Throughout the rest of the decade, regardless of their efforts, material shortages and a decreased demand caused dramatic reductions in Acklin’s work force and Tecumseh's profits. As a result, starting in 1975, a large number of management and supervisory jobs were combined, eliminated, or re-assigned. Employees were forced to increase their efforts of decreasing scrap and increasing productivity.

Throughout the remainder of the 1970s, Acklin was held to a gas and fuel oil quota based on their 1972 usage, a restriction that forced them to cut profits. By 1979, a Federal Energy Regulation was handed down which demanded that the company set the temperature no higher than 65 degrees.

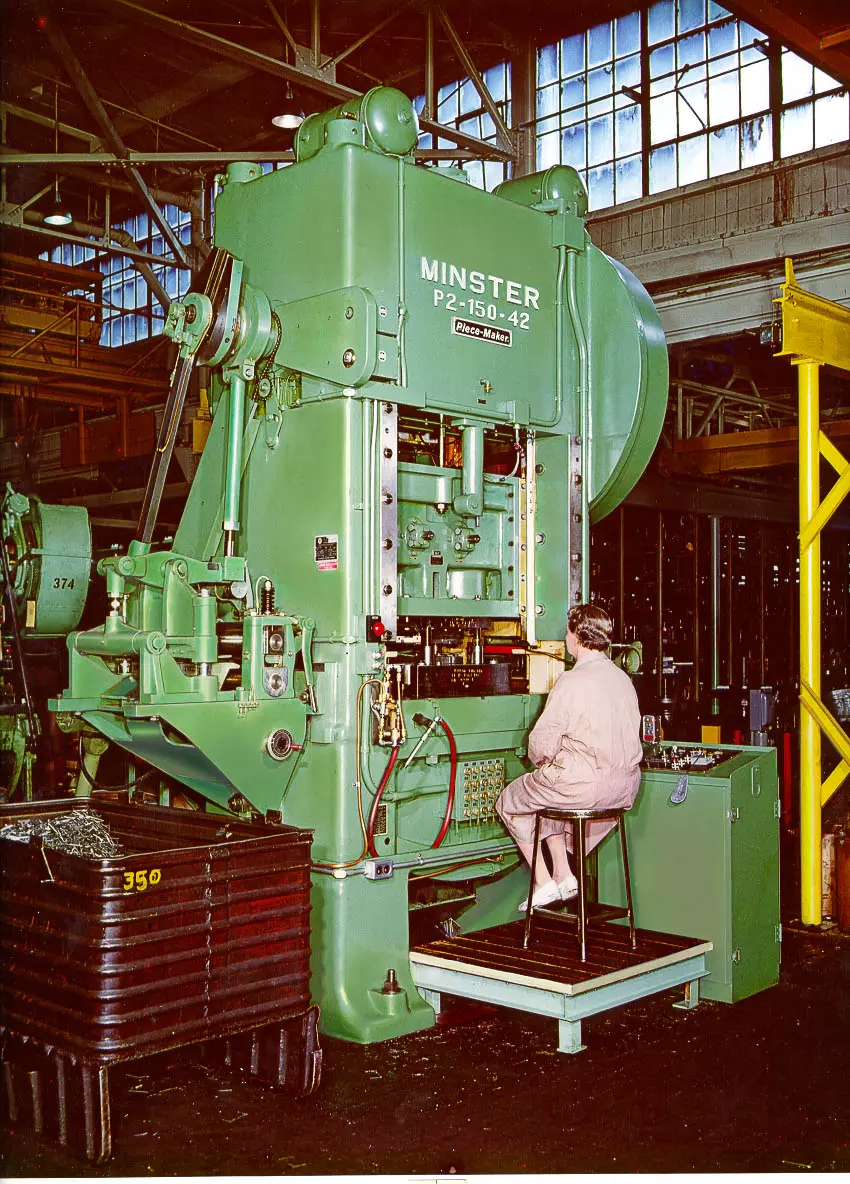

Woman operating Minster Press, 1970s

Woman operating Minster Press, 1970s