Model 118

Model 118

Exhibit Gallery

by Timothy Messer-Kruse

Toledo's Attic and Toledo Scale

Among the most recognized brand names of the twentieth century is Toledo Scale, a company whose headquarters and primary design and production facilities were located in its namesake. One of the greatest achievements of the Toledo's Attic Committee (especially its point man for collections, Ernest W. Weaver, Jr.) during 1998 was securing possession of the corporate papers of Toledo Scale from the Mettler Toledo Corporation. Along with many cases of documents, ledgers, photographs, and other archival materials, the Toledo Scale Collection includes a series of paintings by Georges LaChance of the skilled artisans of the company. In this exhibit, Toledo's Attic Virtual Museum presents a few of the items from this vast collection.

"The First Fifty Years" A Company History by Toledo Scale Company, 1951

HENRY THEOBALD founded Toledo Scale Company in 1901. He had seen opportunities for development in a scale invented by Allen DeVilbiss Jr. that for the first time combined the accuracy of the age-old gravity principle of weighing with the speed of an automatic indication of the weight and computed value. Mr. Theobald was a man of amazing energy, ability, and imagination, as was proved many times in the nearly twenty-five years that he headed the company. He was an "alumnus" of the National Cash Register Company and served there as general manager before coming to Toledo.

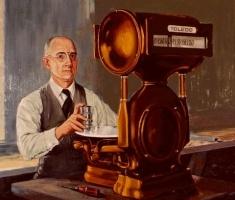

Henry Theobald, founder of Toledo Scale Company

Henry Theobald, founder of Toledo Scale Company

Mr. Theobald was immediately faced with the two characteristic problems of most young companies: the raising of the necessary capital and the marketing of the product. He was successful on both counts, but it is a testament to the rapid growth during the succeeding years of his regime that the sales and manufacturing requirements sometimes ran a close race with the need for additional capital.

The original directors of the company were Henry Theobald, Lenox S. Rose, J. B. Rose, and C. E. Young. The inventor, Allen DeVilbiss Jr., was the first factory manager.

Within five years of the founding of the company, Toledos were appearing on grocery counters in all parts of the country. This was all the more of an achievement when it is recalled that the Toledo salesman was asking the grocer to invest from six to ten times more than the price of the simple balance scale he had been using.

While the early Toledo Fan Scale was excellent for grocery weighing, it soon became apparent that a scale with a cylinder-type chart, giving more computations and added capacity, was needed for the meat markets. In 1906, the first Toledo cylinder scale was placed on the market glorified with a bright blue finish and encrusted with gold filigree. As with the first Toledo, this cylinder scale was also a pendulum-type (no springs) scale. It was also distinguished from some scales then on the market in that its price computations were meticulously accurate. These characteristics eventually evolved into the now famous slogan "No Springs Honest Weight."

Under the continued vigorous leadership of Henry Theobald, the name Toledo "No Springs Honest Weight" was becoming known beyond the borders. Toledos were being shipped to several countries in Europe, and a Canadian subsidiary was established. Sales records were made only to quickly be broken, and it was in 1911 that the 100% Club, now one of the oldest sales-quota groups in the country, was formed.

In 1912, the first Toledo double-pendulum industrial portable scale was introduced. This scale brought very great advantages to industrial weighing, which had previously been limited to the tedious operation of beam-type scales. The now-famous Toledo “800” became the foundation of the Toledo industrial line, which first came into its own due to the increased demand for speed and accuracy incident to World War I.

This period also found the company engaged in an Honest Weight campaign that was to have far-reaching effects in the nation's food stores. There were some scales then in use with prices on the computing charts so arranged that meat could be sold at the same price at which it was purchased and still show a profit. Mr. Theobald, in the interest of both merchants and consumers, did much to focus public attention on the importance of accuracy in weighing and computing. Through these efforts, substantial impetus was given to the enactment of weights and measures legislation in the various states. At the same time, the many dramatic efforts used in promoting sales did much to establish lasting recognition for Toledo and its famous slogan. There were impromptu parades featuring new installations, special signs and banners, sales conventions in elaborate settings . . . and a flood of printed material written with missionary zeal.

As the use of Toledo Scales spread widely, Mr. Theobald gave very early recognition to the importance of adequate installation and maintenance service. He phrased this in the statement, "We are not obligated to make more scales, but we are morally obligated to maintain the scales that we have built." As early as 1908, the company had set up service facilities at the factory, and shortly after that trained the first men to render service in the field, starting a service organization that is today present wherever Toledos are sold throughout the world.

In January 1926, Hubert D. Bennett became president of Toledo Scale Company following the death of Mr. Theobald, introducing another period of important development for the company and its products. Additional capital was brought in, commensurate with the volume of business being done.

By the mid-20s, the long-familiar gold lacquer of food store scales was giving way to white porcelain, and the company organized a porcelain enamel subsidiary to assure a high quality product.

Special devices were becoming an important part of the business. These adaptations of weighing scales to a wide variety of force-measuring applications found many uses, particularly in the automotive field. A subsidiary, Toledo Precision Devices, Inc., was set up in 1929 to produce these specialized items.

The growing line of products forced further plant expansion, and the closely built-up area in which the main factory was located caused the acquisition of small plants that were to be both a symbol of growth and a problem for the next decade.

At the same time, however, the company was making long-range plans. The site on which a new plant was to be built years later was acquired in 1929. Engineering facilities were expanded with a new emphasis on research. A comprehensive sales training program was set up, and service training and facilities were also developed. Foreign sales, under a vigorous expansion program, were contributing importantly to the volume.

In the field, the basic framework of zone and district operation that still exists came into being. The number of company-operated sales and service offices was greatly increased. This close and direct contact between the company and the ultimate users of its products has been important both in rendering efficient service, and also in maintaining a continuous awareness of user needs as a guide to future product development.

In 1929, the directors of the company were H. D. Bennett, Lenox R. Rose, W. C. Gookin, 0. C. Reeves, W. A. Zolg, H. L. Thompson, Rathbun Fuller, W. W. Knight, John T. Rohr, and F. L. Geddes.

With the close and essential relationship of scales to industry and to retailing, it is not surprising that the company, in the early 30s, found itself along with the rest of the national economy in a series of grim years. These problems were met boldly with new products and developments. A Toledo research fellowship at Mellon Institute, Pittsburgh, produced the first naturally white plastic. Seeing opportunities for its application beyond its products, the management in 1931 formed a new subsidiary company to make this material, named Plaskon, an operation that was to prove eminently successful.

Also in 1931, important industrial scale developments were announced, including a new floor scale line with an entirely new type of pivot design. These pivots were self-gauging and reflected the precision machinery being introduced into the factory. In these scales, the pivot accuracy was machined in, instead of being achieved only by tedious adjusting and hand honing, as is still the conventional manner.

Of far-reaching importance was the announcement in 1931 of the first series of Toledo Printweigh Scales. These scales, which provided a printed and identified weight, were as significant a step forward as the first Toledo Industrial Dial Scale had been nearly twenty years earlier.

The excellent sales coverage and nationwide service facilities of Toledo Scale Company had for many years brought into consideration the advantages that could be offered to the food store through lines closely associated with scales. In 1934, the distribution and servicing of choppers, mills, and slicers was added, an arrangement that was to continue until World War II.

The Sentinel Duplex, announced in 1935, typified the coordinated use of research, design, engineering, and manufacturing techniques that were to make this, and succeeding Toledo products, outstanding. The housing was the largest plastic molding made to that time, use of aluminum cut nearly 90 pounds from the weight of the previous model, and a totally new optical system provided new ease and accuracy of reading for the merchant.

In 1938, the continued growth of the company added another subsidiary to the fold: a foundry and heavy machine company in Defiance, Ohio. But these facilities did not solve the basic need for a new plant and general offices at Toledo that would bring together the operations then scattered over some seven plants of varying size and age. The 80-acre site, located on Telegraph Road at the northern edge of the city, had been acquired in 1929. The new plant, completed in the summer of 1939, was so well conceived that it is today practically a prototype for present-era industrial construction. This new plant unshackled the company from space limitations for the important years that were immediately ahead.

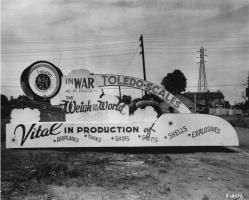

If there had ever been any doubt as to the essential need for weighing equipment in industry and in food distribution, this need was amply demonstrated in World War II. In addition to executing ordnance contracts for precision fire-control equipment, the company, throughout the War period, built scales, under priority, to plant capacity.

The Toledo double pendulum mechanism proved to be one of the most versatile instruments, not only for indicating weights, but for a wide variety of force-measuring requirements. It functioned in Toledo Dynamometer Scales to measure the torque of giant airplane engines, and to test the diesel engines for landing craft. Toledo custom-built equipment then, as now, tested springs for compression and tension and checked piston rings. Continuous weighers tested the uniformity of tire tread stock, while Toledo hopper scales batched the ingredients in the manufacture of synthetic rubber. Huge bombers were checked for balance and loading on special Toledos. Even the much-maligned ration stamps were weighed – to determine the count – on special Toledos.

But Toledo Scale wartime activity was by no means confined to the factory. With the tendency to locate new war plants in unlikely and remote cornfields, the full nationwide coverage of Toledo service and sales put the company in an unusual position to offer assistance when it was needed most, and to be promptly ready for installation and maintenance. Toledo men in the field did an outstanding job in serving scale users in this trying period, and this tribute applies equally to Toledo distributors overseas who, under severe handicaps, carried on to serve their customers.

In spite of the additional facilities made available through the new plant construction in 1939, additions were needed in 1941, 1942, and 1943. These added more than fifty per cent to plant capacity. One of these was a separate building for service training, soon outgrown, but significant in the emphasis given this important function.

To facilitate both the immediate needs and long range projects, Toledo engineering was, for the first time, formally divided into its main functions – research; development; and production engineering – and each set up with separate facilities.

Important changes were also made in the corporate structure during this period. The successful Plaskon subsidiary was sold to Libby Owens-Ford, and the cash realized used to retire a preferred stock issue and for added working capital. The porcelain enameling subsidiary was sold to the management that had operated it since its inception.

At the end of 1945, the fighting of World War II was over and the first of the new post-war Toledo products – the Chopper – was announced.

The cessation of hostilities brought the full impact of pent-up demand for weighing equipment from the industries, institutions, and food stores that had not had the benefit of priorities. The problem of stepping up production to fill this big backlog of orders brought with it an opportunity to introduce into the manufacture of scales the most modern production and assembly methods. While Toledo parts for many years had been standardized and interchangeable to a far greater degree than in the industry as a whole, the assemblies had been made chiefly on a one-at-a-time basis. The management invested heavily in new machine tools, transformed the plant layout for a more effective production flow, and introduced the first complete production lines for the assembly of food store scales. Even the Toledo industrial line, with its more than 45,000 variations of basic types, was found to lend itself to these improved methods to a greater degree than might be imagined.

In 1948, the Guardian 70 Duplex was introduced, a scale unsurpassed today in its reading features; weighing accuracy; and modern beauty.

Within this brief period of five years, the company introduced a complete line of modern food machines, each with major features never before available to users. Following the first Chopper in 1945, a large-size Chopper was added. The Toledo Steak Machine came next, then the Power Meat Saw, and, most recently, the Slicer.

A major sales training program was set up to serve the many new men added since World War II, at the same time the Toledo offices in the field had gone through a continuing program of modernization.

At the beginning of 1946, the Defiance plant was sold, and in March 1949, an entire new line was added through the purchase of the Sterling Kitchen Machine manufacturing operation in Rochester, New York (which has since become the Rochester Division, housed in a new plant in that city).

In spite of the substantial size of the factory and the home office at Toledo, there is actually a larger number of Toledo Scale people in the field than at the Toledo, Ohio, headquarters. This is accounted for in the fact that there are Toledo Scale offices in more than 200 cities in the United States and Canada, and distributors in more than 50 foreign countries. Whether a Toledo is purchased through a company branch, a distributor office, or (in the case of a Toledo Sterling Kitchen Machine), through a franchised dealer, there is assurance that Toledo factory-trained service is close at hand.

Visitors to the Toledo Scale Company headquarters plant tell us of a number of things that they find particularly interesting: the huge, well-kept lawn (and the equally well maintained plant interior); the large areas given over to engineering; the amazing variety of models going through production, from intricate, custom-built batching systems to completely standardized food machine units; the extensive use of modern materials; the high precision maintained both in mass production and in hand operations, such as the sealing of weights; the investment in tooling to assure uniformity of parts; the air-conditioned office areas. Such facilities, quite naturally, bring about a pride in good workmanship that is inevitably reflected in the products. The company's growth has brought in many talented new people, but the large membership in the Toledo Scale Quarter Century Club is ample testimony to the strong background of experience in the organization. A comprehensive pension and group insurance program is in effect; in fact, the company was a pioneer in providing group insurance, the first program being set up in 1916.

Toledo Scale Company is the only manufacturer producing all of the principle types of scales. The start of the second half-century finds the company at its highest level of operation, with its products modernized for fine appearance and outstanding performance. The directors of Toledo Scale Company today are W. W. Knight, John T. Rohr, Harris McIntosh, W. A. Fink, W. W. Knight Jr., Milton Knight, H. Lawrence Thompson, Orrin Wood Sr., C. 0. Marshall, Sr., and W. M. Randolph.

The following pages present some of the highlights of the new Toledos of the Toledo operations away from the headquarters city and of the Engineering program projected far into the future.

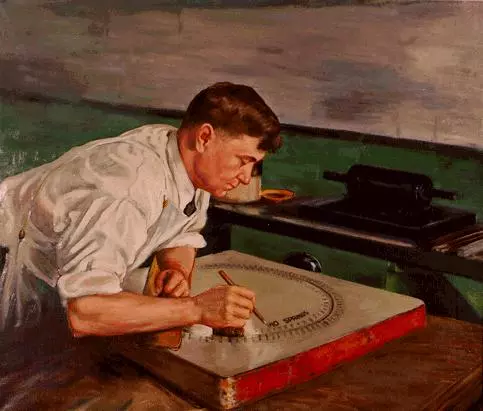

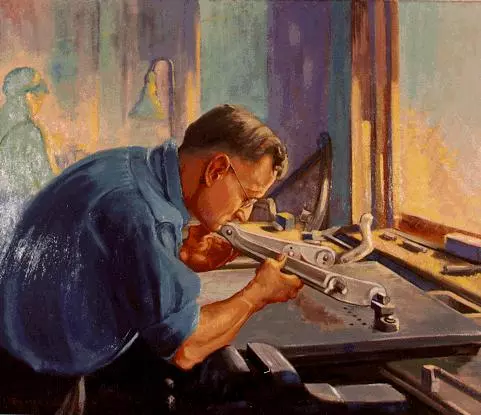

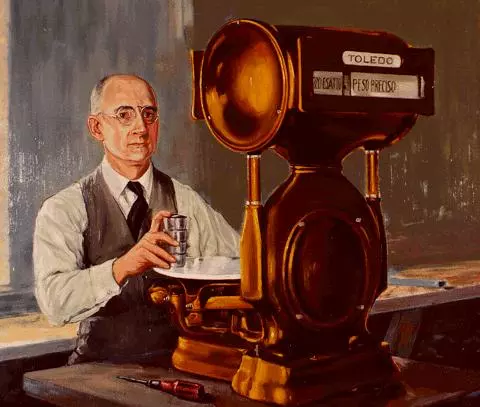

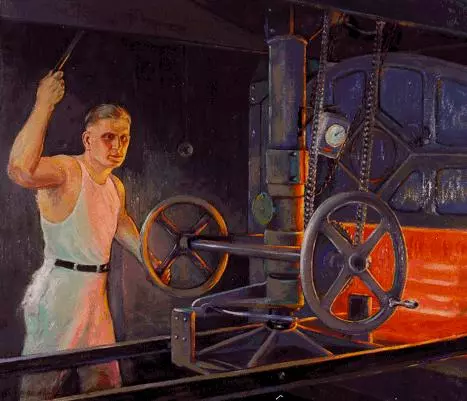

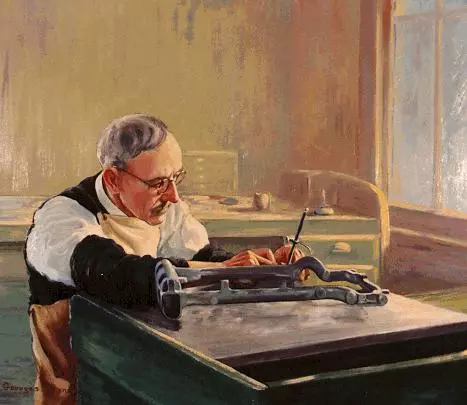

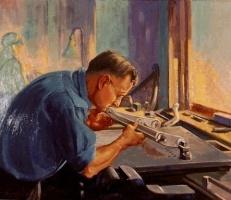

The Toledo Scale Paintings of Georges LaChance

This series of 14 paintings was commissioned by Toledo Scale and created by Georges LaChance in 1928 and 1929. These paintings are of the most senior Toledo employees of that era as they performed their jobs.

The narratives which accompany 8 of the paintings are excerpts from the 1930 article which highlighted these employees as it described the manufacturing process of Toledo Scale.

"Beauty of design, ingenious engineering, the finest of raw materials, efficient production methods and modern machinery, all contribute to the quality of Toledo Scale production. But, to the craftsmanship of its builders, who with skilled hands and years of experience mould these features into the finest and most desirable weighing equipment, the Toledo Scale Company owes it leadership in the scale industry."

Thus begins the article "Craftsmanship of Toledo Builders: A Factor in Weighing Service" from the June 25, 1930 issue of The Toledo System, Jr.

"The finest of modern machinery has a place in Toledo Scale manufacturing, of course, but with it must go the work of artisans, skilled and experienced in the art of scale building. The many craftsmen engaged in the production of Toledo Scales represent its greatest single asset."

The Toledo System, Jr. Volume 3, No. 5 June 25, 1930

C. C. Faylor

"C.C. Faylor, a prominent member of the Chart Department, is a twenty-year veteran. One phase of his work is transferring the chart drawing to the stone, a very particular job. In this work several points must be watched and defects guarded against. The transfer paper must be properly treated. The pressure on the paper must be correctly set so that a good clear reproduction, free from distortion, is made. The etching of the stone, too, requires skill to determine the strength of the acid and length of time in solution for proper etching. Care must be given this operation to make sure that the acid does not uncut the graduations and figures. Such vitally important operations as these can only be entrusted to a man with Faylor's year of experience and reputation for careful and exact work."

Dave Garn

"First in years of service and the best known is Ray Garn, a twenty-four year Toledo Scale man. He has one of the most difficult jobs to perform and equally as important. "Ray" sets pivots in all types of levers and it certainly requires skill and patience if any jobs does. All pivots must be properly located and special gauges are used [to] carefully check this correct position. The accuracy is checked to light, that is, the pivots must fit in the gauges so that no light shows through between the knife edges and the gauge. It is said that light is easily seen through a space of 1/10,000 of an inch so you can see the fine accuracy that is maintained. Honing pivots, too, is sometimes necessary in this work and to hone an accuracy of 1/10,000 of an inch demands the most painstaking work, you'll agree."

J. P. Huntzinger

"J. P. Huntzinger, veteran of eighteen years, was grinding the arcs of sectors while I was in the Machine Department. These curved surfaces must be very accurately ground and free from all waves and scratches. They are tested at the machine and with a special three-dial gauge, one dial for each sector arc, to 1/10,000 of an inch tolerance. This gauge is so sensitive it clearly shows any defect of 25/100,000 of an inch. Huntzinger's ability to hold this important work to such a close tolerance, consistently, is a factor in Toledo quality."

Fred E. Metz

"In the Tool Department there is another of the old line Toledo craftsmen. Fred E. Metz has been with the Company twenty-seven years. His work includes the making of dies, fixtures, master parts and machines. He was working on a master cam when I was there and you can imagine the care and precision this work involves. A master part that is not absolutely correct to the nth degree will throw all parts from which it is made into salvage. Consequently the utmost of skill and accuracy is required. Exceeding care is taken in forming the arc of the master cam to obtain the correct eccentricity and to assure a perfectly true arc, free from waves. Micrometers are used to test this master part to a tolerance of 2/10,000 of an inch plus or minus. You can get some idea of the fineness of the work when you realize that 2/10,000 of an inch is about one-tenth the thickness of an ordinary newspaper. Fred's twenty-seven years of experience has equipped him with unusual ability in performing this important work."

A. W. Meyer

"The first veteran we meet is A.W. Meyer, Foreman of the Polishing, Plating and Soft Wheel Grind Department. "Gus" certainly knows his stuff when it comes to this work. His twenty-eight years of experience lets nothing but the best of work go out of his department. In his work it is important that all surfaces of castings be perfectly clean and smooth in order to assure a perfect finish. On some of the jobs going through this department there [are] as many as eight separate polishing and buffing operations. Here, too, metallic, copper and nickel plating are done. When a part is to be nickel plated a bright as well as smooth surface must be prepared in order to produce a lustrous and perfect plating job."

Walter Palmer

"In the Assembly Department are three employees with more than fifteen years service. Walter Palmer is the oldest and most prominent of the three. He has passed his twenty-seventh year of scale building. Walter scrolls every fan scale that goes out of the factory. He also stamps the patent plate to correspond with the order and attaches it to the scale. He is one of our most versatile members of this department, for he can balance scales, set charts, and assemble a scale complete just as well as he does his regular work. His thoroughness has made him a mighty valuable man."

Jack Rittenhouse

"The oldest veteran Toledoan is Jack Rittenhouse, Foreman of the Enameling Department. He has been with the Company for thirty years and took part in making the first Toledo scale, then known as the DeVilbiss scale. Not only has Jack maintained the high quality of the Toledo gold lacquer finish but he has developed the process and improved the finish greatly. The Toledo gold lacquer finish requires eight separate operations of spraying and sanding. All are performed with the greatest of care. No letup in this respect is ever considered but, on the contrary, each man is doing his best to improve his work. The Toledo lacquer finish is known as one of the finest in commercial use and much credit must go to Jack Rittenhouse."

Otto Teall

"The last department we visit is the Final Inspection, the operations which we covered in a recent issue. Three veteran craftsmen are found on this all important work. Otto Teall, Foreman of the Department, is a twenty-nine year craftsman. . . To (him) is entrusted the responsibility for weighing accuracy in the field. As a result, after the most careful inspection and rigid weighing tests they will pass only an absolutely correct machine."

The following men remain unidentified:

The Early Retail Scales (Gallery)

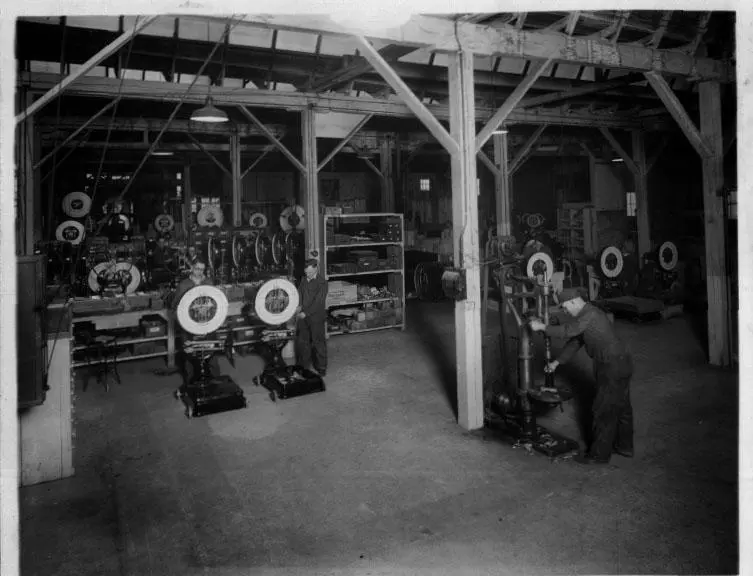

A Tour of Plant One circa 1929

In June of 1929 a series of photographs were taken of plant one, the oldest manufacturing facility in Toledo Scale's growing empire of factories. These photographs provide a unique and remarkable glimpse into the production process at Toledo Scale, a production process that still retained much of the artisanship and hand assembly methods that had been abandoned by many manufacturers in that era of Fordism.

The oldest manufacturing facility in Toledo Scale

The oldest manufacturing facility in Toledo Scale

Tour Gallery

The Process of Die-Making: A Series Showing the Making of the First Plaskon-Cabinet Scale Die

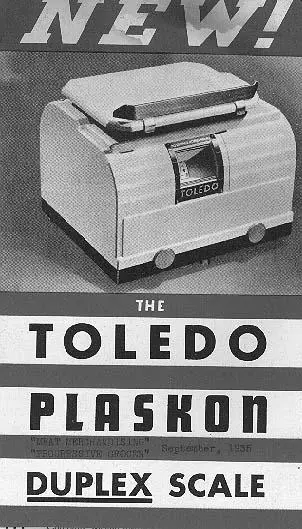

The Toledo Plaskon Duple Scale

The Toledo Plaskon Duple Scale

When we look at our ordinary household objects we seldom appreciate the artistry and craftsmanship that goes into making them. Even our seemingly mass-produced goods begin with a designer's sketch and a sculptor's cut into metal. In the 1930's Toledo Scale introduced one of the earliest plastic appliances, a scale encased in a new material that Toledo Scale patented and dubbed, "PLASKON". The molding of this material required a press of extraordinary dimensions and power. Toledo Scale documented the process of producing the mold that was the master for all subsequent Plaskon scales. In the photographs below, one can begin to appreciate the skill of the artisan that still occupies the beginning of the modern production process.

A Short Chronology of the History of Toledo Scale

- 1901 Henry Theobald founds Toledo Computing Scale and Cash Register Company

- Production begins on Allen DeVilbiss Jr.'s computing scale

- 1902 Company becomes Toledo Computing Scale Company

- 1904 "No Springs, Honest Weight" becomes company slogan

- 1905 Cylinder Scale introduced

- 1910 Windsor, Canada plant established

- 1911 Industrial line begins with development of double pendulum portable scale

- 1912 Company renamed to Toledo Scale Company

- 1924 Death of Henry Theobald

- 1926 H. D. Bennett becomes Toledo Scale president

- 1929 Toledo Precision Devices, Inc. division established

- 1931 Plaskon subsidiary established (plastics manufacture)

- Toledo Printweigh scales introduced

- Toledo wind tunnel scale developed (totally new concept in weight, force measurement)

- 1932 Duplex cylinder scale developed

- 1934 Food choppers, mills, slicers added to production

- 1935 Sentinel Duplex introduced (90 lbs. lighter than former retail scales)

- 1938 Defiance, Ohio plant established (foundry and heavy machine)

- 1939 Telegraph Rd., Toledo, Ohio main plant completed

- 1941-1943 Additions to main plant completed

- 1946 Harris McIntosh becomes Toledo Scale president Defiance, Ohio plant sold; Rochester, N.Y. plant established (kitchen machines)

- 1948 Guardian 70 Duplex retail scale introduced

- 1950 Checkweigher line introduced

- 1952 2000 Series mechanical industrial scale introduced

- Entire dial scale line redesigned

- 1958 400 Series Printweigh line introduced

- 1963 Verilux Projected Indicator scale introduced

- 1965 First desk top digital scale introduced

- 8001 solid state scale introduced

- 1968 Toledo Scale becomes part of Reliance Electric Company

- 1970 Full computer control of weighing process through use of mini-computers and micro-processors began

- 1971 Model 8130 load cell digital indicator scale introduced

- 1974 Model 8180 parts counting scale introduced Model 8201 digital computing scale for retail introduced

- Model 7500 Bridgemaster motor truck scale introduced

- Model 8400 digital computing scale for candy, nuts and confectionary

- 500 Series solid state electronic Printer introduced

- Model 7100, 7200 load cell railroad track scales introduced

- 1976 Toledo Scale official scale of the XXI Olympic Games

A History of Toledo Scale Advertising and Promotions

Although this part of the essay wasn't completed, a gallery had been created to show a series of photographs with businesses weighing products before versus after switching to Toledo Scale.