The Toledo Scale Paintings of Georges LaChance

This series of 14 paintings was commissioned by Toledo Scale and created by Georges LaChance in 1928 and 1929. These paintings are of the most senior Toledo employees of that era as they performed their jobs.

The narratives which accompany 8 of the paintings are excerpts from the 1930 article which highlighted these employees as it described the manufacturing process of Toledo Scale.

"Beauty of design, ingenious engineering, the finest of raw materials, efficient production methods and modern machinery, all contribute to the quality of Toledo Scale production. But, to the craftsmanship of its builders, who with skilled hands and years of experience mould these features into the finest and most desirable weighing equipment, the Toledo Scale Company owes it leadership in the scale industry."

Thus begins the article "Craftsmanship of Toledo Builders: A Factor in Weighing Service" from the June 25, 1930 issue of The Toledo System, Jr.

"The finest of modern machinery has a place in Toledo Scale manufacturing, of course, but with it must go the work of artisans, skilled and experienced in the art of scale building. The many craftsmen engaged in the production of Toledo Scales represent its greatest single asset."

The Toledo System, Jr. Volume 3, No. 5 June 25, 1930

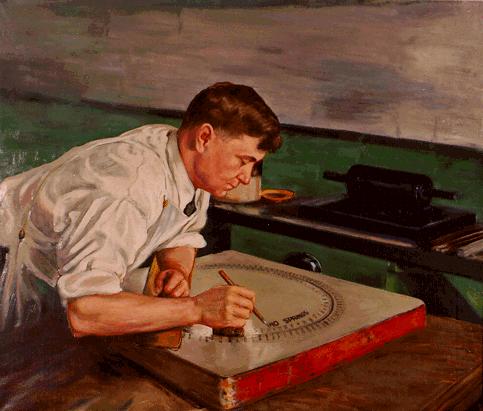

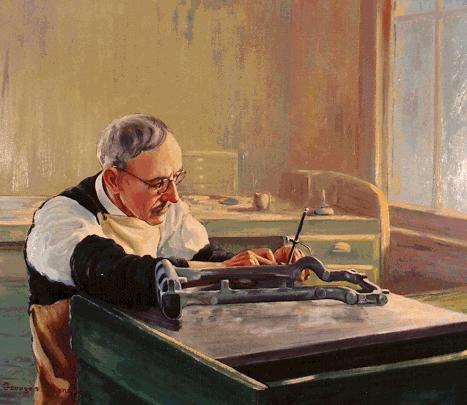

C. C. Faylor

"C.C. Faylor, a prominent member of the Chart Department, is a twenty-year veteran. One phase of his work is transferring the chart drawing to the stone, a very particular job. In this work several points must be watched and defects guarded against. The transfer paper must be properly treated. The pressure on the paper must be correctly set so that a good clear reproduction, free from distortion, is made. The etching of the stone, too, requires skill to determine the strength of the acid and length of time in solution for proper etching. Care must be given this operation to make sure that the acid does not uncut the graduations and figures. Such vitally important operations as these can only be entrusted to a man with Faylor's year of experience and reputation for careful and exact work."

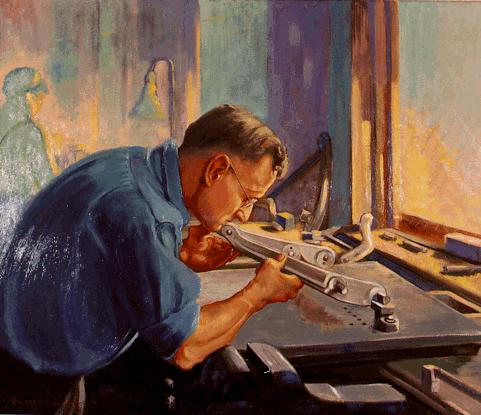

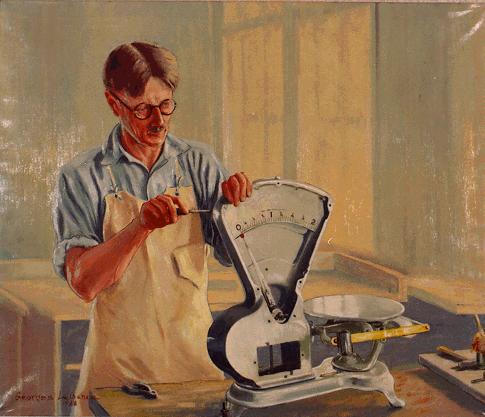

Dave Garn

"First in years of service and the best known is Ray Garn, a twenty-four year Toledo Scale man. He has one of the most difficult jobs to perform and equally as important. "Ray" sets pivots in all types of levers and it certainly requires skill and patience if any jobs does. All pivots must be properly located and special gauges are used [to] carefully check this correct position. The accuracy is checked to light, that is, the pivots must fit in the gauges so that no light shows through between the knife edges and the gauge. It is said that light is easily seen through a space of 1/10,000 of an inch so you can see the fine accuracy that is maintained. Honing pivots, too, is sometimes necessary in this work and to hone an accuracy of 1/10,000 of an inch demands the most painstaking work, you'll agree."

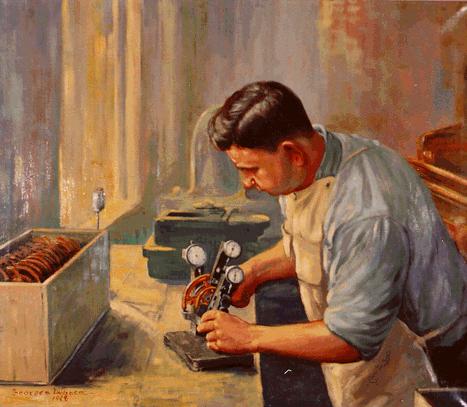

J. P. Huntzinger

"J. P. Huntzinger, veteran of eighteen years, was grinding the arcs of sectors while I was in the Machine Department. These curved surfaces must be very accurately ground and free from all waves and scratches. They are tested at the machine and with a special three-dial gauge, one dial for each sector arc, to 1/10,000 of an inch tolerance. This gauge is so sensitive it clearly shows any defect of 25/100,000 of an inch. Huntzinger's ability to hold this important work to such a close tolerance, consistently, is a factor in Toledo quality."

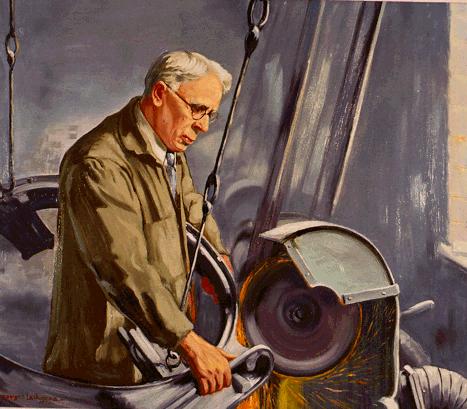

Fred E. Metz

"In the Tool Department there is another of the old line Toledo craftsmen. Fred E. Metz has been with the Company twenty-seven years. His work includes the making of dies, fixtures, master parts and machines. He was working on a master cam when I was there and you can imagine the care and precision this work involves. A master part that is not absolutely correct to the nth degree will throw all parts from which it is made into salvage. Consequently the utmost of skill and accuracy is required. Exceeding care is taken in forming the arc of the master cam to obtain the correct eccentricity and to assure a perfectly true arc, free from waves. Micrometers are used to test this master part to a tolerance of 2/10,000 of an inch plus or minus. You can get some idea of the fineness of the work when you realize that 2/10,000 of an inch is about one-tenth the thickness of an ordinary newspaper. Fred's twenty-seven years of experience has equipped him with unusual ability in performing this important work."

A. W. Meyer

"The first veteran we meet is A.W. Meyer, Foreman of the Polishing, Plating and Soft Wheel Grind Department. "Gus" certainly knows his stuff when it comes to this work. His twenty-eight years of experience lets nothing but the best of work go out of his department. In his work it is important that all surfaces of castings be perfectly clean and smooth in order to assure a perfect finish. On some of the jobs going through this department there [are] as many as eight separate polishing and buffing operations. Here, too, metallic, copper and nickel plating are done. When a part is to be nickel plated a bright as well as smooth surface must be prepared in order to produce a lustrous and perfect plating job."

Walter Palmer

"In the Assembly Department are three employees with more than fifteen years service. Walter Palmer is the oldest and most prominent of the three. He has passed his twenty-seventh year of scale building. Walter scrolls every fan scale that goes out of the factory. He also stamps the patent plate to correspond with the order and attaches it to the scale. He is one of our most versatile members of this department, for he can balance scales, set charts, and assemble a scale complete just as well as he does his regular work. His thoroughness has made him a mighty valuable man."

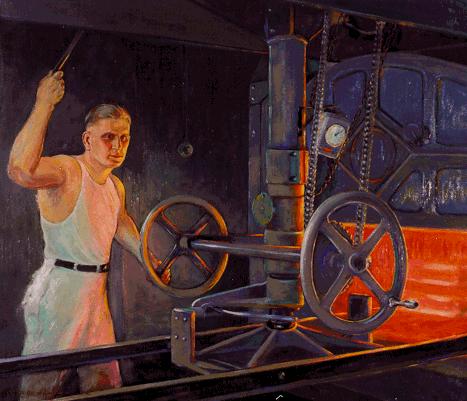

Jack Rittenhouse

"The oldest veteran Toledoan is Jack Rittenhouse, Foreman of the Enameling Department. He has been with the Company for thirty years and took part in making the first Toledo scale, then known as the DeVilbiss scale. Not only has Jack maintained the high quality of the Toledo gold lacquer finish but he has developed the process and improved the finish greatly. The Toledo gold lacquer finish requires eight separate operations of spraying and sanding. All are performed with the greatest of care. No letup in this respect is ever considered but, on the contrary, each man is doing his best to improve his work. The Toledo lacquer finish is known as one of the finest in commercial use and much credit must go to Jack Rittenhouse."

Otto Teall

"The last department we visit is the Final Inspection, the operations which we covered in a recent issue. Three veteran craftsmen are found on this all important work. Otto Teall, Foreman of the Department, is a twenty-nine year craftsman. . . To (him) is entrusted the responsibility for weighing accuracy in the field. As a result, after the most careful inspection and rigid weighing tests they will pass only an absolutely correct machine."

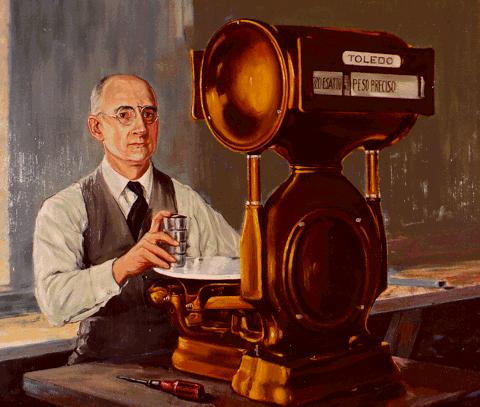

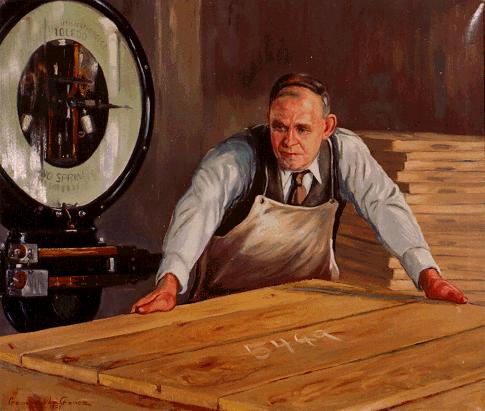

The following men remain unidentified: