III. The War Effort -- "...because of your production on that day, the defeat of Japan has been brought closer..." - May 11, 1945 - Letter from the War Department to "the Men and Women of Acklin Stamping Company"

A. Toledo During World War II

When World War II began, Toledo was ready. In June of 1940, nearly a year before the United States entered the war, the Toledo Board of Education began to emphasize vocational programs for high school students in an effort to ensure that Toledo plants would receive defense contracts. Their efforts (and Toledo’s already present industrial base) paid off when, during the summer of 1940, Toledo industries began to receive defense contracts. In July 1940 the E.W. Bliss company, parent of the Toledo Machine and Tool Company, announced a $9.5 million dollar contract about the same time Willys-Overland announced a $25 million dollar contract. In all, Toledo received over $900 million dollars in defense orders, enough to put employment figures at the highest they’d been since 1929. Many plants, including Acklin, went to 24 hour, 7 day a week production.

With many men going to war, women began going to work by the thousands. In 1942, the first nursery opened in Toledo in order to meet the demands of mothers working in the factories. These women didn’t only work in factories, however; in fact, they filled a variety of positions from auto-mechanics and bus drivers to freight handlers for the Railway Express Agency.

B. Acklin During World War II

During the mid 1930s, Acklin began experimental work for the Government on eye pieces to be used in gas masks. By the late 1930s, Acklin began to take production orders from the British and Swedish military governments for these eyepieces, as well as depth charges and other munitions. When America entered the war in December of 1941, Acklin's entire production was shifted to the war effort. In fact, the demand on Acklin was so high that the plant added an additional 25,000 square feet in 1943 to facilitate production.

Women working at Acklin during the war

Women working at Acklin during the war

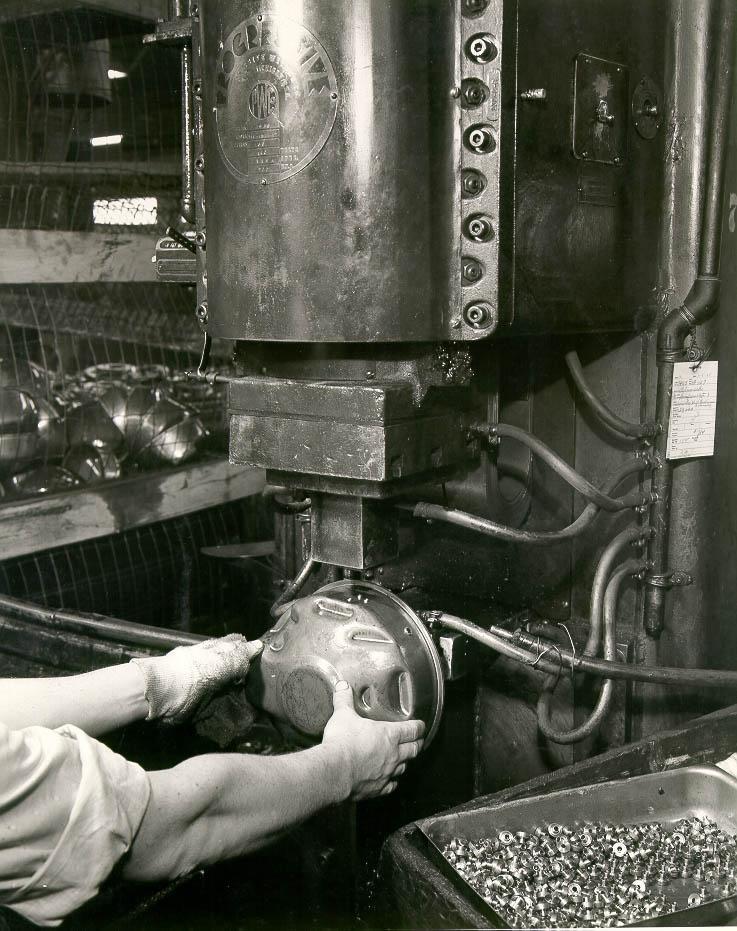

For the war effort, Acklin produced a wide variety of products, but the bulk of their output was 20mm; 40mm; 75mm; and 105mm shell casings. The production of these shell casings required for the first time the use of automatic lathes. Rough forgings arrived at Acklin via New York Central Railroad from a variety of sources. It was Acklin's job to turn these into finished shell casings. The first step in this process involved hollowing out the centers of each shell. These shells were then turned on a lathe, roughly. A hole was bored into the nose of each shell, and then the nose of each shell was tapped, expanding the hole. Following that, the open end of each shell was shaped into a point and both ends were polished. A base was then welded to the face end of each shell before each nearly completed shell casing was turned on a lathe a final time. The shell casings were then subjected to rigorous testing before being heat treated, shipped, and packed.

Acklin also made parts used in Willys-Overland's trucks and Jeep production, 30 caliber machine gun mounts, the metal canisters used in flame throwers, and even parts that they found out later were used in the atomic bomb.

The work was difficult and many employees would later recall the constant observation and inspection and the long hours. Inspection was especially important on these parts because any error could create a shell which would not function properly, an error that could mean lives in the course of battle. Maintaining high levels of production with a fairly small number of employees resulted in long, hard hours for those who remained.

Ray Mierzwiak, who had worked for 18 cents an hour unloading coal cars during the Depression, was willing to take advantage of the work now available. He began putting in 14-hour days, 7 days a week, on the shell line. He earned $1.15 an hour, nearly a dollar more per hour than he had earned during the Depression. Many other employees put in long hours for the war production

effort, an undertaking which peaked in October of 1944 when Acklin had 175 people working in the production department - 103 women and 72 men.

During the war effort, Acklin women, like women across Toledo and the country, worked alongside the men on the shell line, operating large presses, lathes, and dies. Previously, women had been relegated to working on the small lines, using smaller presses that could be operated sitting down to produce parts such as window sash pulleys and muffler parts for automobiles. During WWII, however, there was a shortage of males to operate the big line presses. Encouraged by government posters of Rosie the Riveter, women across the country and at Acklin stepped up to the job. Following the end of the war and the return of a large number of male workers, the women returned to the small line presses.

Acklin employees showed a remarkable dedication and earnestness in their production. In fact, in May of 1945, the War Department sent a letter of commendation to Acklin's employees, noting that "on V-E Day men and women of Acklin Stamping Company, without exception, remained on the job producing parts." The letter goes on to commend them, stating that unlike those who left their machines to celebrate "you people, with broader vision, and knowing that the hardest part of the job is still to be done, remained steadfast at your points of duty."