IV. Tecumseh Products Steps In, 1952-1964

A. Tecumseh's History

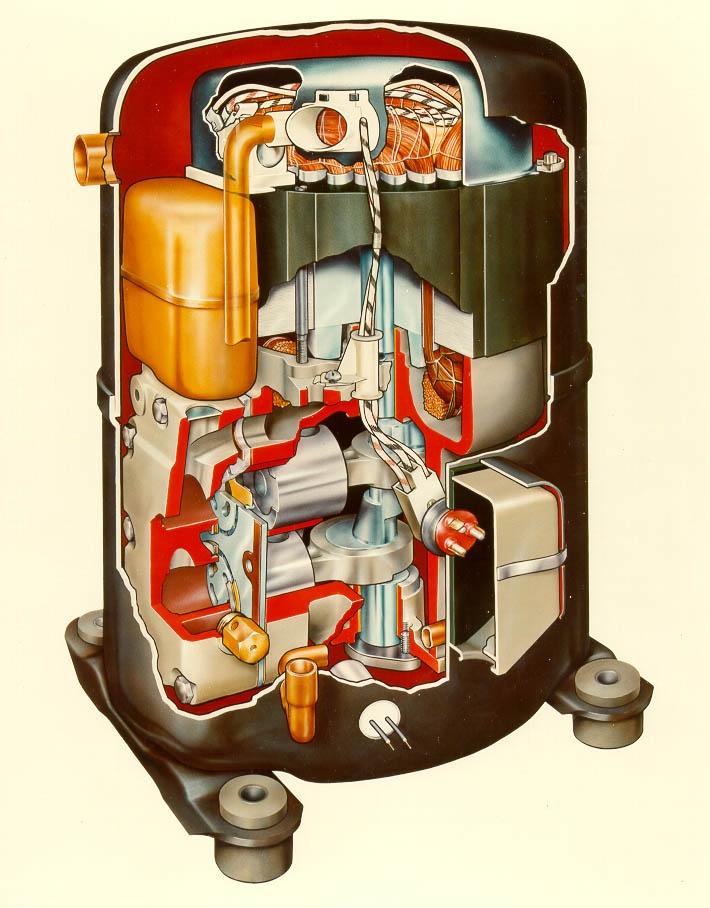

The Tecumseh Products Company actually started in Hillsdale, Michigan in 1932, 21 years after Acklin was formed. In that year, Raymond Herrick and two of his friends formed the Hillsdale Machine and Tool Company, an organization devoted to the manufacture of automotive parts. They had, however, an idea for better refrigeration parts and in 1934 they purchased a 50,000 square foot plant in Tecumseh, Michigan and changed their name to Tecumseh Products. In 1938, they brought out the first hermetically sealed refrigeration unit, but this line of business was sidelined for war production in the following years. By 1947, Tecumseh was a leader in the refrigerator compressor industry. In November of 1950, they purchased the Universal Cooler Company of Marion, Ohio, branching out into the air conditioning business.

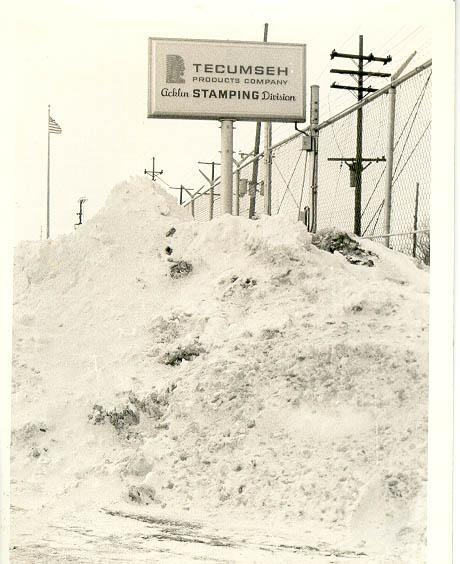

In July of 1952, Tecumseh Products announced its purchase of the Acklin Stamping Plant. Tecumseh had originally planned on building a new plant in Michigan and moving Acklin's employees and equipment, but Acklin refused, not wanting to "break a good organization," so the company stayed in Toledo. Initially, there were no changes to the company’s management structure. Several Acklin executives took positions on Tecumseh's Board of Directors, and Tecumseh's President and Secretary took positions on Acklin's board.

B. Acklin Production Under Tecumseh, 1952-1954

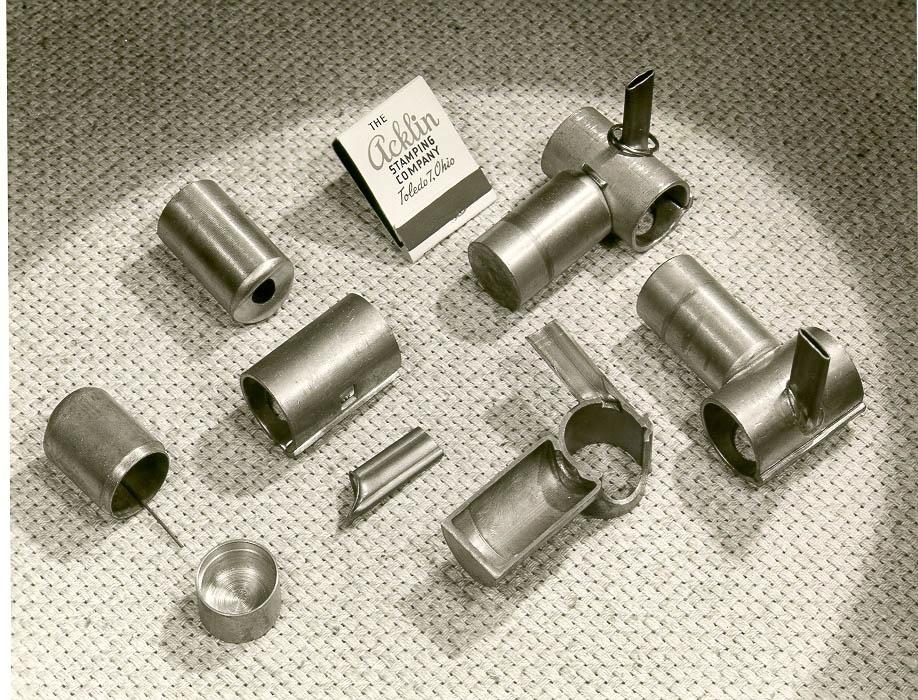

Essentially becoming Tecumseh Products in-house stamping plant, Acklin's production of Tecumseh-related goods expanded, quickly becoming the bulk of Acklin's output. Acklin continued to stamp a variety of other outside parts, including parts for major automobile manufacturers. These other stamping jobs helped to stabilize the cyclical production schedule involved in the production of air conditioners and refrigerators.

Following World War II, rising incomes and lowered prices created an increased demand for a wide variety of luxury goods. Technological advances made by the government during the war were utilized for the first time in such civilian goods as air conditioners, refrigerators, automobile engines and bodies, and televisions. Tecumseh was uniquely positioned to capitalize on this growing demand, and their business grew dramatically.

Air conditioning production began in the winter with maximum output coming in February, March, and April in order to send these casings to assembly factories where they would be included in the actual units, ready for sale during the hot summer months. August was the slowest time for this production and as a result the plant would shut down for two weeks each August, during which time a majority of the employees would take a vacation while some would do general maintenance, repair, and improvements work on the plant.

In 1953, as the demand for refrigerators and other cooling devices increased, Tecumseh approved approximately $45,000 in plant expansions and new machinery purchases in order to increase output. To accommodate these new orders, Acklin ordered more expensive steel than they usually used and hired a large number of new employees. But skilled employees were hard to find. Following the war, many returning veterans went to college and took jobs above the factory production level, and more and more high school graduates were following the same path.

The spring of 1953 saw the Big Line busy producing housings for room air conditioners. Sales of these appliances were up from previous years and Acklin was there to meet the demand.

C. Acklin Becomes a Division of Tecumseh Products -- Greenhill Steps Down, 1954

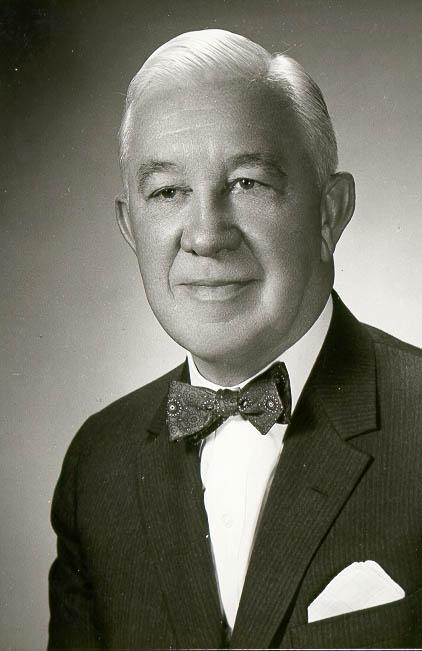

In 1954, the Acklin Stamping Company became the Acklin Stamping Division of Tecumseh Products. In the turnover and re-alignment, President Cyril Greenhill left the presidency, retaining his position as the Chairman of Acklin's Board of Directors. In his place, Alvin E. Seeman, an Acklin employee since 1929, assumed the presidency. Ralph Meyer became the company's Treasurer while Harry Smith, Vice President in Charge of Production since 1944, remained in that position.

Alvin Seeman began his career 1920 as a treasurer at the Dura Corporation. He left Dura in 1924 to become a Senior Accountant at the firm of Knopak, Hurst, and Dalton. He came to Acklin in 1929 and served as an auditor, and over the next 8 years he worked his way up to the Treasurer position. In 1940, he was made a Vice President of the company while retaining his Treasurer duties. In 1944, he was promoted to Executive Vice President, and when Tecumseh purchased Acklin in 1952, he became a member of Tecumseh's Board of Directors while retaining his position at Acklin.

Seeman’s official title, reflecting Acklin's new position in Tecumseh's corporate hierarchy, was Executive Vice President of Tecumseh Products, General Manager of Acklin Stamping Division. Effectively, Acklin no longer had its own President, but merely a Tecumseh Vice President in charge of the Acklin Division.

Under Alvin Seeman's leadership and through Tecumseh Product's financial investment, Acklin entered a new period of economic stability during the second half of the 1950s. The transition to Tecumseh Products benefitted Acklin in a number of ways. Raymond Herrick, Tecumseh’s President at the time, had, like Greenhill, worked his way up from the ground floor. As a result of this he saw and understood the needs of the workers and tried hard to foster a sense of community and kinship among all of Tecumseh’s employees.

Cordia Ross, a press operator on the small line during this time, remembered Herrick:

“We used to call him the Big Man, you know. He used to give us turkeys for Christmas.... and he said he gave us turkeys for Christmas so we would have something on our tables for the holidays because when he was growing up they were poor and they couldn’t afford turkeys.”

Tecumseh also supplied Acklin with steady work, at least during the 1950s and 1960s, allowing them a sort of stability and regularity they hadn’t had since World War II. Tecumseh’s capital investments allowed Acklin to remain competitive with new machines and equipment.

In 1955, under Tecumseh Products, a safety program was introduced. Large amounts of money were put into upgrading presses, providing safety gear, and promoting knowledge of safety among the workers. This program was a dramatic and immediate success, with the number of lost time days due to industrial injuries (those significant enough to require medical attention) dropping from an average of 5000 per year from 1950-1954 to 498 in 1955.

A new labor contract negotiated in 1955 between Tecumseh and the union was described by Lewis Mattox, union chair, as the best contract ever negotiated at Acklin. The terms of the contract included comprehensive hospital coverage, disability provisions, and the availability of discounted life insurance for employees.

The 1957 contract that would carry the company through the decade went even further. After a 30-hour bargaining session, Tecumseh granted each of Acklin's 600 employees at least a 7 cent per hour raise, and an even larger amount for 170 skilled workers. The contract also provided increased vacation pay, and increased sickness and accident benefits. All of these provisions were fairly expensive, costs which were offset by ever increasing production and rising profits.

Production and profits were indeed booming for Acklin and Tecumseh during the late 1950s and early 1960s. In the spring of 1956, using nearly 5,000 pounds of steel per hour, the plant was producing at nearly 100% capacity. This production set records for Acklin. During the months of March and April, over 35,000 compressor housings were made each day, for a total of 766,000 housings in March and 742,000 in April. By October of 1956, Acklin employed 650 individuals, had a monthly payroll of $250,000, and used 160 tons of steel each day.

This period of rapid expansion and increased production continued until 1959, when a major steel strike, colder weather, and declining demand forced a fairly severe round of layoffs - 61 men and 18 women. By 1961, the average pay at Acklin was up to 2.49 per hour, a decent salary, but including benefits provided through the labor contracts that salary cost Tecumseh 3.33 an hour, well above the local or national average.

Tecumseh had established itself by the early 1960s as America's largest producer of compressors, making 70% of the compressors used in window air conditioners, 70% of the compressors used in automobile air conditioners (outside of GM, which made its own), 70% of freezer compressors, and 30% of refrigerator compressors. The number of units sold annually climbed for Tecumseh from 356,000 in 1941 to 5,659,000 in 1962. Sales increased as well, growing from $7 million a year in 1941 to $184 million in 1962. Tecumseh Products had clearly grown from the small company in Raymond Herrick's garage into an important international business.

During the late 1950s, in an effort to diversify its holdings, Tecumseh Products purchased several smaller companies in a variety of manufacturing fields. It picked up the Lauson Engine Company and Taylor Products in 1956, both manufacturers of gasoline engines. In 1957, Tecumseh bought out the Power Products Company of Grafton, Wisconsin, known for its production of two cycle engines. The Ohio Semi-Conductor company of Columbus, Ohio was purchased by Tecumseh in 1960, and the Peerless Gear and Machine Company of Dunkirk, Ohio followed a few years after. This diversification allowed Tecumseh to cope with the both the cyclical nature of compressor production and provided them with alternative business as the refrigeration market shifted out of its explosive first decade to become an item purchased mainly by replacement buyers and newly-married couples.

During the 1950s, Tecumseh Products also became increasingly involved in the international market. Rather than produce compressor housings domestically and then export them to Europe and the rest of the world, Tecumseh Products opted to franchise its designs to other companies. Tecumseh would provide, for a substantial fee, the drawings and plans for the construction of these compressors to an independent company. Tecumseh would then provide training and consulting expertise to the new company and would also receive a royalty percentage of that company’s profits. This business model, although it didn't affect Acklin's production directly, allowed Tecumseh to achieve high profitability.

Employment and work continued steadily throughout the early 1960s. During this period Acklin maintained between 600 and 700 employees, depending on the season and production demands.

In 1965, Alvin Seeman, after nine years at Acklin's helm, relinquished his position as General Manager at Acklin to Phillip Wood. Seeman remained an Executive Vice President of Tecumseh Products, however, and a member of Tecumseh's board. This transfer of power marks another important shift in Acklin's history.